Field Services, Fuel Pipe Balancing Valves, and CFD Modeling

Field Services

EES STEP Combustion provides a full complement of field services for fuel conversion products and boiler optimization, customized to address annual tune-ups and assessments per the US EPA Major Source Industrial Boiler MACT.

Specific capabilities include burner and flame pattern inspections, component replacement, and all associated burner management system adjustments. Inspections are tailored to control air-to-fuel ratios and CO emissions consistent with manufacturer’s specifications. STEP Combustion’s service capabilities extend to any of its emission and fuel conversion products, including boiler optimization, combustion performance testing, diagnostic testing, fuel studies and energy assessments.

STEP Combustion offers continuous, real time coal mass flow systems, coal velocity measurement systems, portable coal flow measurement systems and coal pipe balancing services.

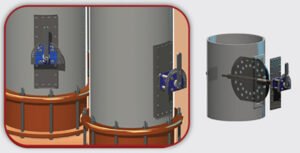

NT Series (NTS) Adjustable, Diffusing Coal Valves offer precise control of mass flow and velocity for burner to burner fuel balancing of coal fired power plants. Available features and options include:

- Balance coal distribution pipe-to-pipe

- Improve in-furnace temperature distribution

- Increase combustion efficiency and reduce emissions in minutes

- Perforated damper blades designed to dissipate coal ropes for improved homogeneous mixture to burners

- Hardened steel components (AR Plate) for longevity in highly erosive environments

- Arc spray coating is available for higher wear applications, as well as silicon carbide for extreme wear protection

- Manually or electrically actuated

- Precise “lock-in” positioning for optimum control of flow

Engineering & CFD Modeling

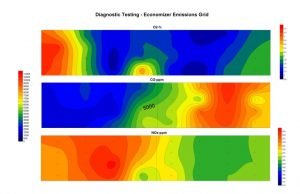

Economizer Outlet Emissions Grid for a 800+ MW Utility Boiler

Whether for troubleshooting, baseline equipment evaluation, or system design, our team of engineers uses the latest computational fluid dynamics (CFD), finite element analysis (FEA), and other numerical modeling applications.

- SNCR & SCR Performance

- Soot

- Slagging and Fouling

- Heat Transfer

- Stress Analysis

- Fluid and Particle Dynamics

- Combustion Modeling

- NOx & Pollutant Formation Chemistry