Boiler Performance Optimization

Water Treatment

Air Pollution Control

Burners & Fuel Conversions

Burners & Fuel Conversion

New Burners and Retrofits

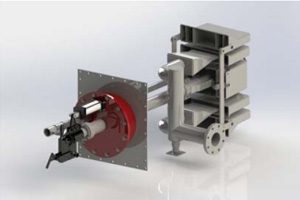

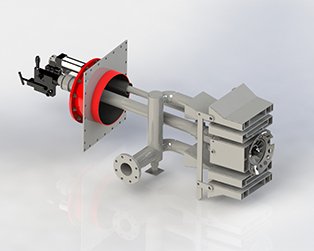

T-Fire Burner Modification

Through our STEP Combustion group, EES provides complete burner upgrades for new or existing coal, gas, oil or biomass boilers. STEP Combustion burner systems including windbox, fuel trains, burner management systems, fans, and controls (SCADA, etc.) have been provided to customers world-wide. STEP Combustion can supply new burners from our line of multi-fuel burners or, as in many cases, STEP can provide custom burner upgrade kits for existing burners. New and upgraded burners have been provided for wall, opposed, and tangentially fired boilers, package boilers, heaters, dryers, and more.

For burner retrofits STEP begins with an analysis of the existing burner including: aerodynamic model of the combustion air, computational fluid dynamics (CFD) combustion model, as well as fluid dynamic models of the fuel delivery equipment. A low NOx burner (LNB) upgrade is designed to suit the existing burner and furnace arrangement. In most cases, STEP Combustion can utilize the existing burner register and fuel delivery equipment to provide a low NOx design which rivals new low NOx burner performance. Typically, upgrades are very economical at only a fraction of the cost of a new burner, and highly efficient owing to STEP Combustion’s expertise in low NOx high efficiency aero and fluid dynamic burner design.

The burner upgrade begins with an analysis of the existing burner including an aerodynamic model of the burner combustion air, as well as computational fluid dynamics (CFD) with combustion modeling. A low NOx upgrade is designed to suit the existing burner arrangement. In most cases EES STEP Combustion can utilize the existing burner register and fuel delivery equipment to provide a low NOx design which rivals new low NOx burner performance. Upgrades are very economical and a fraction of the cost of new burner due to EES STEP Combustion’s expertise in air register, combustion air control and balancing.

VARISWIRL™ Coal & Gas Burner

STEP’s technology for burners retrofit

- Aero and Fluid dynamic analysis of existing burner

- Hardware designed to suit the existing burner, avoiding unnecessary expense

- In many cases, aerodynamic & fuel injection hardware alone are replaced to provide good low NOx performance

Fuel Conversion

Through burner replacement or strategic retrofit, STEP has designed, engineered, and supplied gas and multiple fuel conversion burners for both fuel co-firing and complete fuel conversion applications with burner sizes ranging from 30 to 300 MMBtu/hr.