Boiler Performance Optimization

Water Treatment

Air Pollution Control

Burners & Fuel Conversions

Process Monitors

ZLD and MLD Systems

EES provides total water management solutions to the power generation market. Our KLeeNwater team designs, fabricates, installs and operates water treatment systems custom tailored to address specific plant water recovery or disposal requirements. Through the selective application of both physical and chemical water treatment techniques, EES enables power plants to treat and recycle wastewaters for re-use or minimize discharge wastewater to the point of Zero Liquid Discharge (ZLD). Our KLeeNwater solutions are very effective in removing contaminants including arsenic, nitrates, selenium, bromides, chlorides and total suspended solids, many of which are called out in the USEPA Coal Combustion Residual (CCR) and Effluent Limitation Guidelines (ELG).

EES provides total water management solutions to the power generation market. Our KLeeNwater team designs, fabricates, installs and operates water treatment systems custom tailored to address specific plant water recovery or disposal requirements. Through the selective application of both physical and chemical water treatment techniques, EES enables power plants to treat and recycle wastewaters for re-use or minimize discharge wastewater to the point of Zero Liquid Discharge (ZLD). Our KLeeNwater solutions are very effective in removing contaminants including arsenic, nitrates, selenium, bromides, chlorides and total suspended solids, many of which are called out in the USEPA Coal Combustion Residual (CCR) and Effluent Limitation Guidelines (ELG).

Combined Cycle Gas Turbine (CCGT) Power Plants

Water requirements within CCGT plants include high purity make-up water to the heat recovery steam generator (HRSG), water for injection into combustion turbines for power augmentation or NOx control, and make-up water for combustion turbine evaporative coolers, fogging systems, and cooling towers. Of these water service requirements, cooling towers present the major impact on make-up water usage and wastewater discharge.

As make-up water sources are highly variable and can include graywater or low-quality groundwater, high levels of suspended solids, copper, and zinc are challenges that are readily addressed with effective pre-treatment followed by KLeeNwater membrane processes. Combining these processes with brine crystallization results in total water re-use (ZLD solution) as shown below:

Coal Fired Power Plants Utilizing Wet Flue Gas Desulfurization (FGD)

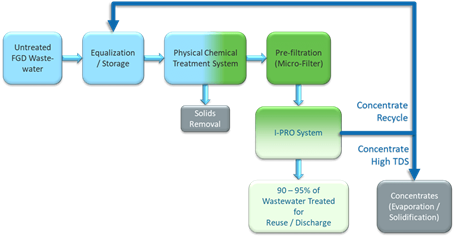

In addition to the EPA’s ELG rules, coal fired plants also have to comply with the Coal Combustion Residuals (CCR) rules which will lead to pond closures, wet to dry bottom ash conversions and a need for water reuse or Zero Liquid Discharge (ZLD). The final rule requires, among other things, ZLD for bottom ash and fly ash, and physical/chemical plus biological treatment for FGD scrubber wastewater. KLeeNwater advanced pre-treatment chemistry coupled with membrane technologies allows customers to replace the need for complicated biological systems and ensures a very small component of the influent will be left to evaporate or solidify and complete Selenium and other heavy metals removal. KLeeNwater allows for the reuse of closed loop bottom ash purge flows in the FGD.

Key Benefits of KLeeNwater for Coal Facilities

- Load cycling is not a problem – System can be shut off and on without issues

- Capable of managing varying fuel sources – The membrane treatment technology treats varied fuel sources with no impact on the quality of treated water

- Meets current ELG regulations – Capable of meeting voluntary BAT limits

- Significant reductions in chlorides, bromides, sulfates, boron, metals, and all forms of selenium for local permitting

With EES, your plant can achieve 100% ZLD for the fraction of the capital investment for more traditional ZLD systems.

| Why Work With EES? | Industries We Serve |

|

|