Boiler Performance Optimization

Water Treatment

Air Pollution Control

Burners & Fuel Conversions

Process Monitors

Wet Scrubber

KLeeNscrub

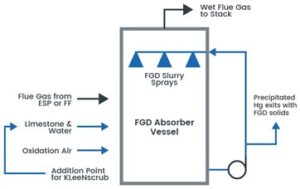

KLeeNscrub is a suite of highly efficient organosulfur-based precipitants for mercury capture in wet and dry flue gas desulfurization systems. Additionally, these additives remediate other heavy metals of concern within power plant waste waters including lead, copper, cobalt, cadmium, zinc, iron and other metals thereby preventing contamination of soil and/or ground water.

Environmental Energy Services, Inc. continues to expand commercial sales of KLeeNscrub mercury precipitants for MATS compliance. The technology is based on an easy to maintain injection system that applies the reagent either through one of the recirculation lines feeding absorber sprays, into the absorber atomizer, or directly into the absorber slurry reservoir. The injection equipment includes a control system to monitor the amount of precipitant in the absorber slurry using a sulfide specific ion electrode. This is an effective tool for controlling dosage and predicting mercury removal performance. KLeeNscrub chemistry has proven its effectiveness in controlling mercury reemission and reducing overall mercury levels at the stack with all coal types in a variety of scrubber conditions. KLeeNscrub is supplied in both tote and bulk tank truck quantities.

Key Benefits of KLeeNscrub

- Mercury reduction is competitive with sorbents such as activated carbon without the concerns of re-emission

- Highly economical when used in combination with proper scrubber operating conditions

- Captures & remediates additional metals: lead, copper, thallium, cobalt, cadmium, nickel, zinc, iron, silver, tin

- Efficient mercury precipitation mechanism prevents re-emission

- Non-corrosive and non-hazardous options; manufactured in the USA by EES

- Large, stable precipitant for easy removal of solids, passes TCLP and thermally stable for wall board processing

- EES can formulate KLeeNscrub additive packages to customize mercury partitioning and solids handling

- KLeeNscrub application equipment is inexpensive and easy to maintain

KLeeNscrub mercury mitigation products include: non-hazardous/low toxicity chemistry options, highly impactful/immediate ORP response options, and products designed for better fine-particulate sweeping/removal.

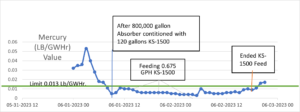

The graph below shows results from a trial feeding KS-1500. Upon completion of the trial, the utility immediately transitioned to a commercial KLeeNscrub customer.

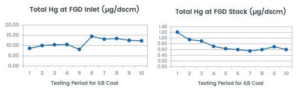

The graphs below represent influent and effluent Hg for a large, commercial WFGD treated with KLeeNscrub.

Mercury Oxidants

EES. offers a complete line of mercury oxidants from halogenated oxidants like Calcium Bromide and Magnesium Chloride to proprietary catalytic oxidants. Mercury oxidation depends on several factors, including the halogen content of the coal and whether or not the plant has an SCR with enhanced Hg oxidation catalyst technology. In the case of Subbituminous or Lignite coals, natural oxidation is sometimes difficult and an additive is needed to promote oxidation during combustion.

EES. offers KLeeN-Ox for Hg oxidation. Some KLeeN-Ox products are patented and licensed to EES.

Key benefits of KLeeN-Ox

- More cost effective as compared to current oxidants

- Less corrosive as applied to the fuel prior to combustion or in SNCR/SCR applications

- Soluble in Urea or Aqua Ammonia for SNCR/SCR application

Dry Scrubber

EES has dry scrubber treatment products for use in dry scrubbers with atomizers or in circulating dry scrubbers. The unique nature of the patent pending chemical enables mercury oxidation and removal all in one product. The dry scrubber KLeeNscrub product replaces some of the single product programs as well as some of the two product programs that are in the market. KS-2325 effectively and efficiently removes mercury as shown in the graph below from a recent evaluation.

Graph of KS-2325 in a dry scrubber with atomizer.

Additional highly successful trials have been performed leading to commercial applications and acceptance of KS-2325.

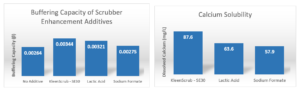

Scrubber Enhancement – KLeeNscrub SE

EES developed the KLeeNscrub SE suite of chemicals to assist in SO2 removal and to help scrubber-limited systems run at higher capacities. Development of the SE line was initiated by utilities’ need for more effective and efficient DBA replacement chemistry. EES personnel performed numerous product evaluations in our treatability laboratory prior to rolling out our initial KLeeNscrub SE-30 product. EES has developed several organic acid products that:

- Increase the solubility of limestone

- Increase the absorption rate of SO2

- Increase the precipitation of Gypsum.

| Why Work With EES? | Industries We Serve |

|

|